The difference is that a maintenance wash uses an NaOH solution in certain rows (see below), while a maintenance rinse uses water in those rows. The washes and rinses are also done at different intervals.

When to Perform a Maintenance Wash or Rinse

Perform maintenance washes and rinses for all positions at the following occasions:

Occasion

Action

2 weeks after last maintenance wash or rinse

Maintenance wash or rinse

2 months after last maintenance wash

Maintenance wash

Position has been idle for 1 week or more

Maintenance wash

Instrument or position will be idle for 1 week to 1 month

Maintenance rinse after the last run before the idle period

and

Maintenance wash before the first run after the idle period

Instrument or position will be idle for more than 1 month

Contact How Do I Contact Customer Care? to schedule a service appointment for draining your system

Instrument or position will be idle for 1 week or more after a maintenance wash

Maintenance rinse

You can also initiate a manual maintenance wash or rinse outside these intervals, for example, to clear the lines of the instrument of salt accumulation.

Consumables & Equipment

• Milli-Q water (or better).

• Reagent-grade (or better) 5% sodium hypochlorite (NaOCl), for example: https://www.sigmaaldrich.com/US/en/product/sigald/239305.

• Maintenance wash only: 1 M NaOH stock solution.

• G4 Maintenance Kit (part number 700,002), which has the following components:

Item

Description

Quantity

Maintenance Sample Cartridge

G4 empty sample cartridge (reusable)

4

Maintenance Reagent Cartridge

G4 empty maintenance reagent cartridge (reusable)

4

Maintenance Wash Cartridge

G4 empty wash cartridge (reusable)

4

Maintenance Flow Cell

G4 maintenance flow cell (reusable)

4

• Instead of the Maintenance Flow Cell, you can also use a regular used flow cell for each position that needs a maintenance wash or rinse.

Performing a Maintenance Wash or Rinse

If you want to initiate a maintenance wash or rinse from the ICS prompt, do the following :

1. For each position you want to wash or rinse, make fresh:

- a. 2 mL 0.01% sodium hypochlorite by diluting sodium hypochlorite stock solution in water.

- b. Maintenance wash only: 200 mL 0.1 M NaOH by diluting 20 mL of 1 M NaOH stock solution in 180 mL water.

If you are washing or rinsing multiple positions, multiply volumes by the number of positions.

2. Rinse all wells of the maintenance cartridges with water to remove any dust or particulates that may have accumulated in the cartridges.

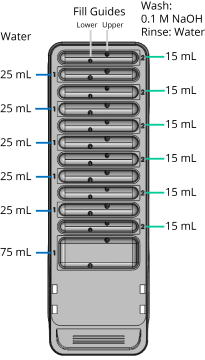

3. Fill the maintenance cartridges with the following reagents:

Note

The Maintenance Reagent Cartridge has lower and upper fill guides in every well. As long as you fill the well above the lower fill guide and below the upper fill guide, there is enough volume for the maintenance wash or rinse.

Cartridge

Location

(counted from top of picture)

Wash or Rinse Reagents

Volume

Image

Maintenance

Reagent

Cartridge

Rows 2, 4, 6, 8, 10

Rows marked 1

Water

In between fill guides

(25 mL)

Rows 1, 3, 5, 7, 9, 11

Rows marked 2

Wash: 0.1 M NaOH

Rinse: Water

In between fill guides

(15 mL)

Row 12

Row marked 1

Water

In between fill guides

(75 mL)

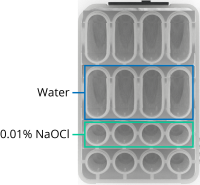

Maintenance

Sample

Cartridge

All wells in row 2

Water

1.2 mL per well

All wells in row 3

0.01% sodium hypochlorite

0.4 mL per well

Maintenance

Wash

Cartridge

Top (bulk) compartment

Water

200 mL

Small rinse well

Wash: 0.1 M NaOH

Rinse: Water

9 mL

4. Start the wash protocol one of these two ways:

• Select the Start Wash in the ICS prompt.

• Go to the Instrument | Maintenance section in the Instrument Control Software and select Wash.

5. Unselect the positions you do not want to wash or rinse (see Figure 1). By default all positions are selected.

Figure 1 Confirming maintenance wash positions with positions 1, 3, and 4 selected, and position 2 unselected.

6. Load the consumables as prompted.

WARNING

The flow cell stage may still be hot from the previous run. Be careful not to injure your hands.

The reagent sippers are sharp. Be careful not to touch as you can injure your hands.

CAUTION

Be careful when loading consumables to avoid spilling, because the cartridges are not sealed. If you do spill buffer, promptly clean up with a dry low-particulate wipe before proceeding the maintenance wash or rinse.

Make sure to always wear gloves when handling reagents, waste, or spills.

WARNING

Waste contains formamide, a suspected carcinogen and reproductive toxin, and other potentially hazardous chemicals. Personal injury can occur through inhalation, ingestion, skin contact, and eye contact. Wear protective equipment, including eye protection, gloves, and laboratory coat appropriate for risk of exposure. Handle used reagents as chemical waste and discard in accordance with applicable regional, national, and local laws and regulations through a licensed hazardous waste contractor.

7. Follow the instructions in the Instrument Control Software. For an explanation of the flow cell position light colors, see What Do The Flow Cell Compartment Lights Mean?

8. If you performed a maintenance wash and the instrument or position will not be used for 1 week or more, perform a maintenance rinse.

9. After the maintenance wash or rinse has finished, rinse all maintenance cartridges the following way:

- a. Rinse all wells in the maintenance cartridges with Milli-Q water. Make sure no NaOH or sodium hypochlorite remains in the wells.

- b. Put the maintenance cartridges upside down and let dry in the air.

- c. Store the maintenance cartridges in a closed dust free box when dry and not in use.

CAUTION

Failure to clean and correctly store maintenance cartridges can result in fluidic system damage to the Instrument.